Date: 26 Oct 2021

Issue

Brake performance is poor. Car not stopping as expected. Brake pedal “spongy” or there is a lot or travel before brakes engage. Brake pedal needs to be pumped to obtain best brake performance.

Brake fluid is DOT4 hydraulic oil (I think originally it was DOT3 but this is no longer available. Hydraulic oil is lovely stuff it strips grease and paint off just about anything – your hands, your car, your tools – anything it touches. If you do spill it wipe it off whatever it is on quickly then wash with water.

Hydraulic oil and water are an odd thing. Hydraulic oil likes to absorb water. This is one of the main reasons why you might need to bleed your system periodically to maintain brake performance. Water in your hydraulic brake fluid is bad. What happens is that when the brakes are applied the calliper or drum unit gets really hot. Hydraulic fluid can withstand heat whereas water will boil and make steam. Steam can be compressed whereas hydraulic oil cannot. So when there is steam in your hot oil brake performance degrades (rapidly sometimes!)

Also, take a look at your master cylinder in the engine bay. It is possible the pump seals are failing and fluid is escaping through the seal leading to poor performance – a quick test is to push the pedal and keep pushing, it is goes down the floor with resistance then this indicates a seal fail in the master cylinder or leaks in the callipers or drum cylinders – fix any leaks or poor seals first. To see leaks in the callipers or drum cylinders take wheels and for rear the drums too off and inspect. If not obvious system leaks then suspect master cylinder faulty.

Note: if bleeding the clutch system a faulty cylinder either master or slave will make changing gear much harder!

All the above are indicators of braking performance issues.

Diagnosis

If the brake pedal can be pushed to the floor with no resistance – DO NOT DRIVE THE CAR – it is likely there is no fluid in the system or the something bad has happened.

If brake performance is poor and pumping the pedal improves the pedal pressure then it is likely the fluid has air in it (air compresses), or there is a small leak and a rapid pumping is enabling fluid pressure to build up.

Before bleeding the system, and if you are unsure, check the brake is working on each wheel. To do this jack up each wheel so it is clear of the ground and spin the wheel then apply brakes. The wheel should stop and with brakes applied not turn at all.

If the wheel does not spin freely then suspect the brake unit is ‘binding’ and fix this first. A binding wheel heats the brake unit and boils the fluid introducing air bubbles that cause brake system to fail.

Binding front discs are an easy to identify and potentially dangerous culprit and the calliper needs servicing before any other repairs are undertaken.

Binding rear drums are more difficult to identify and will degrade brake performance but the fronts ‘should’ still work. Again fix these first.

Assuming other brake checks have been completed then bleeding the system will repair any damaged or moisture laden fluid.

Repair

There are several methods and tools available to bleed a brake system.

The first thing to know is which hydraulic fluid to use.

I use Dot4 rated brake and clutch fluid. I am pretty sure Dot3 would be fine as well but as said above it’s not very common. Other modern cars use a range of different oils. Get the right oil for your car i.e. Hydraulic DOT4 oil.

NEVER MIX ANY OILS

If you unsure, be prepared to bleed the entire system to be on the safe side.

Bleeding the brake system changes the fluid in the system.

Hydraulic systems rely on the fluid in the system not being compressible (only gases can be compressed)

Hydraulic fluid naturally absorbs moisture. If there is moisture in the fluid in the calliper itself then the water will boil when the calliper is hot making steam which can be compressed (refer paragraph above). When this occurs the brake pedal feels soft or can disappear altogether.

The hydraulic fluid will itself boil if hot enough (that’s really bad), this would indicate a calliper fault (often rust related).

The bleeding process

The bleeding process is the same for all bleed points, the objective to remove any air bubbles and moisture contaminated fluid from the system.

This process is the same for the clutch cylinder located on the side of the gearbox bell housing and a git to get to when lying on you back in the rain.

Automatic system bleed tools can be used.

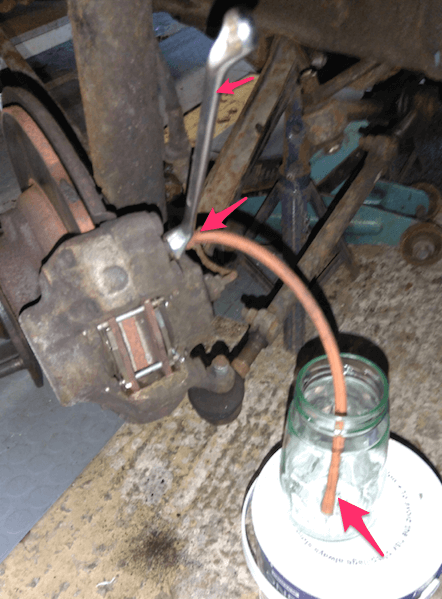

I use a 2-person, manual, bleed process as follows:

- Open the bleed point (person 1)

- Depress brake pedal slowly (person 2). Person 1 monitors fluid stream for air and bad fluid (fluid should be clear).

- Close the bleed point (person 1)

- Release the brake pedal slowly (person 2)

- Repeat 4 or 5 times (both)

- Check fluid reservoir level (person 1)

When hydraulic oil quality is good, i.e. no air bubbles appear in the bleed and the fluid appearing is completely clear, then that part of the system is done.

If you have the wheels with the bleed nipples behind them off the car when bleeding the system the process is easier – but this is not essential.

There are 3 parts of the system to bleed:

- Front right (usually 5 or 6 pedal pumps)

- Front left (usually 6 or 7 pedal pumps)

- Rear (requires 10 to 12 pedal pumps)

For a really bad system, bleed the system twice to absolutely sure all air and contaminated fluid is removed (not normally required unless the fluid comes out ‘black’ indicating it is really bad)

Note: bleed nipples like any other metal part on a car are susceptible to corrosion. If the bleed nipple is worn i.e. the nut is rounded off or nearing its end of life I recommend replacing it. Replacement is easy, simply unscrew and remove and insert new nipple. This is so much easier when you can still get the nipple to open – once the nipple is rounded off you are into a territory of swearing and worst case having to replace callipers and drum cylinders which is dull and expensive. Also don’t leave rounded brake nipples for the next car owner they will not thank you.

The order to bleed the circuits in does not really matter although I usually go front right, front left, rear.

The number of pedals pushes to bleed each part does matter as some parts of the circuit are larger than others.

For near side front I use 6 or 7 pedal presses.

For the off side front I use 5 or 6 pedal presses.

For the rear cylinders 10 to 12 presses.

Parts

Approximate prices from: 2 Jan 2023

| Part | Description | Supplier | Cost |

|---|---|---|---|

| DOT4 Hydraulic Fluid x 0.5 litre | Halfords | £6.99 |

Leave a Reply